Latest Research

- 2023.09.01

- Shishido-Kubo Group

Fabrication of oriented collagen films with high Young's modulus towards high-strength biomaterials

Collagen is the most abundant protein in mammals and has been continuously studied over the past several decades. One of the most useful approaches for maximizing the function of collagen is the orientation control of collagen due to their structural anisotropy with ~300 nm in length and ~1.5 nm in diameter, i.e., for Type I collagen. For example, it has been reported that an oriented collagen tube transplanted as a blood vessel graft, taking an advantage of its high mechanical strength. Several strategies to achieve the orientation of collagen molecules have been proposed, such as electrospinning, and flow-induced alignment; however, most of these orientation methods are limited to fibrous and fibril scales, i.e., 50 nm to 500 nm in diameter. Thus, difficulty in macroscopic orientation on a practical scale (such as several centimeters) prevents to make full use of the advantages of orientation control. Indeed, the macroscopic tensile strength of the oriented collagen bundle (~400 MPa) is much lower than that of collagen fibrils (~2 GPa). thus, uniform collagen orientation control over a large area has a potential to provide a high-strength oriented film.

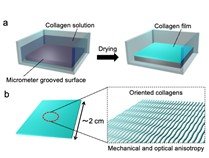

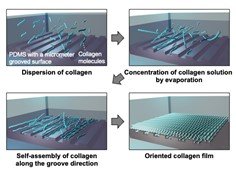

Here, we successfully developed a formation process of uniformly oriented collagen film over a large area, just by drying a dilute collagen solution on a polydimethylsiloxane (PDMS) substrate with a micrometer grooved surface (Fig. 1).[1] This process has great advantages to practical applications due to its simplicity, efficient orientation in a large area, and high mechanical strength.

|

|

| Fig. 1. | Schematic illustrations of (a) the fabrication process of the collagen film by drying on a micrometer grooved PDMS substrate and (b) the fabricated film with oriented collagens.[1] . |

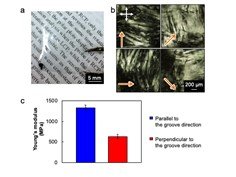

Fig. 2a shows a photograph of a collagen film fabricated on the micrometer grooved PDMS substrate, exhibiting optical transparency. Observation of the collagen film by polarized optical microscopy (POM) revealed that the film has the optical anisotropy (Fig. 2b), and the optical axis of the anisotropy was found to be parallel to the groove direction, which indicates that the collagen molecules oriented parallel to the groove direction. In contrast, a collagen film fabricated in a glass box with a flat PDMS substrate did not show the optical anisotropy in any directions. These results imply that the emergence of the optical anisotropy in the collagen film was attributed to the presence of the micrometer grooves in the film formation process. In addition, we carried out the tensile test of the collagen films to evaluate the mechanical anisotropy along the groove direction. As a result, the Young's modulus calculated from the stress-strain curves showed a clear difference in the tensile directions; the Young's modulus parallel to the groove direction became higher than that in the perpendicular direction (Fig. 2c). These results indicate that the mechanical directionalities were linked with the orientation directions of collagens. It is important to note that the orientation process of the collagen enables not only fabricating the collagen film with high mechanical strength but also providing the mechanical strength anisotropy.

|

|

| Fig. 2. | (a) Photograph and POM images of a freestanding collagen film (size: 2 cm x 2 cm; thickness: 20 µm) fabricated on the micrometer grooved PDMS substrate. The orange arrows indicate the groove direction in the film. The white arrows denote the direction of the polarizers. (b) Young's moduli of the collagen films fabricated on a substrate with micrometer grooves. In the collagen films fabricated on the micrometer grooved PDMS substrate, the films were elongated parallel or perpendicular to the groove direction. [1] |

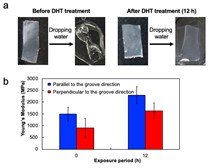

To provide a function of insolubility in water, which is an important factor for practical use of collagen films, we conducted a thermal crosslinking reaction. Dehydrothermal (DHT) treatment is known as a common method of crosslinking collagen molecules, which exposes collagens to raised temperature under vacuum. We evaluated water solubility of the thermally crosslinked film. The untreated film was immediately swollen in water and finally dissolved; however, the crosslinked film thermally treated for 12 h kept its shape in water without swelling (Fig. 3a). The tensile testing showed higher Young's modulus, keeping the relationship of the strength in parallel and perpendicular elongation directions (Fig. 3b). These results clearly indicate that the DHT treatment of the oriented collagen film brought about the crosslinking reaction, which leads to the increase in Young's modulus and water insolubility, maintaining its mechanical anisotropy.

|

|

| Fig. 3. |

Results of the effect on dehydrothermal (DHT) treatment. (a) Photographs of collagen films before and after dropping water on the film. (b) Young's moduli of collagen films as a function of the exposure period of DHT treatment. [1]

|

The orientation of collagen molecules achieved in the present system can be rationalized by assuming that liquid-crystallinity of the collagen is the main factor. Fig. 4 shows schematic illustration of the proposed formation mechanism of the oriented collagen film based on the present system. Drying the solvent leads to concentration of a collagen solution and increases the intermolecular interaction of collagen molecules, and then the collagen solution becomes liquid-crystalline. On the basis of the established theory, orientation of liquid crystals is affected by a surface grooved structure of a substrate. The liquid-crystalline collagens self-assembled along with the groove direction in the PDMS surface, resulting in the orientation of collagen molecules over a large area. By laminating the collagens by repeating the casting process, the collagens are accumulated, maintaining their orientation. We consider that the collagens are densely packed through the film thickness direction because the film shows optical anisotropy at any positions in the thickness direction, and this brings the high mechanical strength.

|

|

| Fig. 4. |

Schematic illustrations of the orientation mechanism of collagens on the micrometer grooved PDMS substrate. [1]

|

In conclusion, we reported a facile fabrication process for the molecularly oriented collagen films over a large area (2 cm x 2 cm). The fabricated freestanding film showed the optical and mechanical anisotropy due to the orientation of collagens. In addition, the thermal crosslinking reaction made the film water-insoluble and increased the mechanical strength, keeping its anisotropy. To the best of our knowledge, this is the simplest example of fabricating oriented collagen film over a large area. This process is expected to widely open the use of the collagen materials for practical applications such as biocompatible substrates with optical and mechanical anisotropy, large-area functional scaffolds for accelerating the development of research in cell biology, and soft robotic materials.

| [1] | M. Aizawa, H. Nakamura, K. Matsumoto, T. Oguma, A. Shishido, Mater. Adv., 2, 6984-6987 (2021). |