Latest Research

- 2023.10.01

- Yamaguchi-Kuroki Group

New Approach for Polymer Modification with Controlled Surface Properties and Its Application to Antifouling Porous Membranes

The issue of global water shortage, especially in developing countries, is one of the development goals of the SDGS, and this challenge should be addressed urgently. To solve this problem, water production technology using water treatment membranes, which is low-energy consumption and environmentally friendly, is attracting great attention. However, large-scale implementation of water treatment membranes requires a solution to the fouling problem. Fouling is a phenomenon that causes reduced separation performance and a reduction of treated water volume due to the gradual blockage of membrane pores due to the adsorption of substances contained in the water. The elimination of fouling requires specialized techniques such as chemical cleaning and backwashing, which has been a bottleneck to the introduction of systems in regions where water shortages are severe.

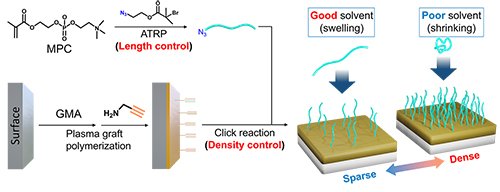

To solve this problem, attention has focused on membrane modification technology utilizing zwitterionic polymers. Zwitterionic polymers can provide antifouling properties due to the strong hydration layer on the surface of the material, which inhibits the adsorption of foulants. However, since the optimal modification state varies depending on the type of feed water, a new technology that allows tuning of the polymer morphologies according to the water quality is still essential. In this study, we synthesized a zwitterionic polymer (poly(2-methacryloyloxyethyl phosphorylcholine): PMPC) with a desired molecular weight by atom transfer radical polymerization (ATRP), and further developed a new method to control the brush density by tuning polymer morphology during the modification (Fig. 1).

|

|

| Fig. 1. |

Schematic illustration of the precise control of zwitterionic polymer brush onto the membrane surface.

|

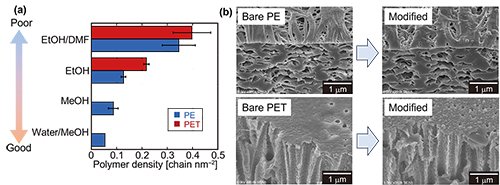

The molecular weight of PMPC was controlled by adjusting the initiator/monomer ratio in the reaction solution, and polymers with different molecular weights with a narrow molecular weight distribution (Mw/Mn = 1.2) were synthesized. For membrane modification, by using our original plasma graft polymerization method, reactive sites were uniformly formed in the pores of porous membranes (polyethylene (PE) or polycarbonate (PC), maximum pore size ~200 nm, membrane thickness ~25 µm). Polymer modification was performed using a highly efficient and selective click reaction, and the density was successfully varied by changing the solvent species (Fig. 2a). In this reaction, high density can be achieved under poor solvents because the polymer is in a shrinking state, and low density can be achieved under good solvents because the polymer is in a swollen state. Furthermore, the pore structures are maintained even after polymer modification, suggesting that the membranes can be applied for water treatment application.

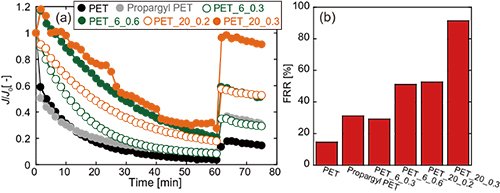

The antifouling performance of porous membranes with different brush structures (i.e. different molecular weights and densities) was further evaluated by permeation of a bovine serum albumin (BSA: 1 g/l as model protein) to the membrane using a dead-end type apparatus for fouling evaluation. PE-based membranes have an intricate pore structure, thus, there was almost no change in permeability. Meanwhile, PET-based membranes have cylindrical pores, making it possible to properly evaluate fouling behavior. In bare PET membrane, the flux decreased rapidly and hardly recovered even after membrane cleaning. On the other hand, in the case of higher molecular weight and denser polymer brush, not only flux reduction was suppressed, but also the recovery rate was extremely high (Fig. 3a). By defining flux recovery ratio (FRR: the ratio between initial flux and flux after cleaning), it was indicated that brush surface with high molecular weight and high density could achieve FRR more than 6 times of an unmodified membrane (Fig. 3b).

|

|

| Fig. 3. |

(a) Relative flux of pristine and modified PET membranes as a function of filtration time. (b) flux recovery ratio of the pristine and modified PET membranes after BSA fouling.

|

In summary, we have successfully evaluated the dynamic fouling behavior of the membrane with different zwitterionic brush states. To the best of our knowledges, the simultaneous control of the molecular weight and density of the modified polymer brushes has never been achieved, and attempt to systematically correlate brush state with membrane fouling phenomena is a new approach to solve fouling problem. The membrane surface design method presented here is expected to become an important technique for achieving appropriate membrane modification states for each water quality in the future.