Latest Research

- 2017.05.08

- Shishido-Kubo Group

Photo-Polymerization Induces Two-Dimensional Molecular Orientation without Polarized Light or Dye Molecule

In soft materials, such as polymers, colloids, and liquid crystals (LCs), both chemical structures of components and their orientation patterns are playing important roles for the manifestations of highly functional properties. Recently, although many soft materials have been developed based on synthetic approach, rational processes for creating materials possessing complex molecular orientation patterns over large areas have attracted much attention. One of the key materials for such orientation control is a LC, which has the intrinsic complex orientation exhibiting large changes in order when subjected to external stimuli such as heat, electricity, or light. 1-3 To date, spatial control of one-dimensional (1D) orientation patterns using LCs have been explored for enhancing the functionality of soft materials, especially for the application in electronics, photonics, soft-actuators, and etc. Until now, however, there is still a few numbers of methods for creating two-dimensional (2D) orientation patterns in soft materials.

Among the advanced techniques for controlling molecular orientation, photoalignment is proposed as the most powerful one. 4-7 In this procedure, there mainly exist two processes using polarized light; one aligns molecules through photochemical reactions of photocrosslinkable, photoisomerisable, or photodegradable compounds, and the other causes molecular reorientation via photophysical interaction between optical electric field and dye molecules doped in its system. Thus, conventional photoalignments always require irradiation of polarized light with dyes that discolor the materials and deteriorate its optical and mechanical properties. Moreover, these have a difficulty in creating complex 2D orientation pattern over large areas that needs precise and dynamic control of polarized light. To circumvent the critical issues for the arbitrary control of molecular orientations, we have designed a simple, general photo-physicochemical method demonstrating that photo-polymerization, of a photochemically inert monomer and crosslinker, through a photomask caused molecular diffusion following the alignment from 1D to 2D patterns. The method requires no alignment layer, no polarized light, or no dye molecules. 8

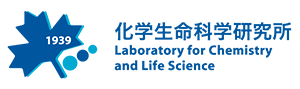

We prepared a sample mixture, composed of a cyanobiphenyl acrylate, a crosslinker, and a photoinitiator absorbing ultraviolet light. The sample mixture was melted above its isotropic temperature, and injected into a 3-μm-thick handmade glass cell, adhering two cleaned glass substrates with glue including silica particles. Subsequently, the cell was vertically irradiated with 365 nm ultraviolet (UV) light for 10 min through a photomask with a line-space pattern (pattern pitch: 500 µm), termed masked photo-polymerization (Fig. 1). Observation of the resultant polymer film with polarized optical microscope (POM) clearly showed a uniform 1D optical anisotropy at every boundary between the irradiated and unirradiated regions. Further investigation using polarized UV-visible (UV-vis) absorption spectra of the resultant polymer film revealed that the absorbance in the absorption wavelength of the cyanobiphenyl moiety exhibited its highest and lowest values with polarized light parallel and perpendicular, respectively, to a vector direction normal to the boundary. This means that the optical anisotropy is generated by the 1D orientation along the vector direction normal to the boundary. Conversely, photo-polymerization without a mask gave rise to a polymer film possessing no uniform optical anisotropy but a random poly-domain orientation structure. These observations clearly show that photo-polymerization with spatially distributed light intensity is crucial for generating a uniform 1D molecular orientation.

Figure 1. (a) A micrograph of the line-space photomask used for masked-photopolymerization. (b) Polarized optical micrographs, (c) polarized ultraviolet-visible absorption spectra of the resultant film polymerized for 10 min. The scale bar is 100 µm and arrows show the vector direction normal to the lines of a mask.

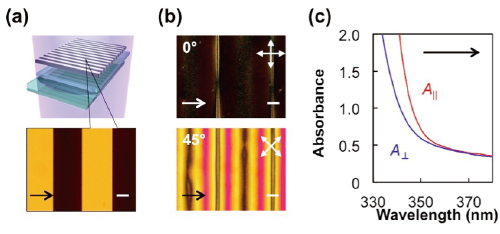

To understand the detailed orientation behavior, we directly measured the surface profile of polymer films with a surface profiler by opening the glass cell with a cutter (Fig. 2). The measurements revealed that the surface structure of the film was embossed. We found both that the apex of the surface structures was centered on the irradiated region and that the periodicity depended on the line-space pattern of the mask. In addition, the height of the apex drastically decreased by ∼500% when the masked photo-polymerization time decreased from 10 min to 1 s. These results and previous theoretical and experimental explanations, based on the Flory-Huggins theory suggest that the formation of embossed structures arise from the accumulation of molecules in irradiated regions owing to molecular diffusion towards them during masked photo-polymerization. Considering the suggestion, it has been shown clearly that a uniform 1D molecular orientation spontaneously occurs by the diffusion of molecules. First, photo-polymerization through a mask causes molecular diffusion at the boundary between the irradiated and unirradiated regions. Because of the difference of chemical potentials between these regions, molecules diffuse towards the irradiated ones along the vector direction normal to the boundary. Along the direction of diffusion that imposes shear stress on molecules, the anisotropic molecules of cyanobiphenyl ones are aligned.

Figure 2. Surface profiles of the films polymerized via masked-photopolymerization for 1 s and 10 min. Black arrow show the vector direction normal to the lines of the photomask.

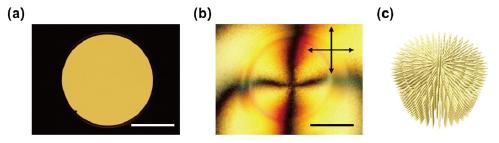

Of particular interest is that the present photo-physicochemical orientation method, which allows us to control molecular orientation direction depending on the vector direction normal to the boundary of irradiated regions, principally enables one to create 2D molecular orientation patterns merely by photo-polymerization with a desired spatial design of photomask. Here, we employed a 200-μm-diameter pinhole as a photomask, and the masked photo-polymerization resulted into a film having a radial molecular orientation pattern, as shown in Fig. 3. This result indicates that further development of the present method would open a new pathway for creating more complex, orientation patterns over large areas without alignment layer, polarized light, or dyes. Taking into account that the driving force is molecular diffusion occurring in all materials, further investigation will provide the novel techniques for fabricating specialty films with highly functional properties by aligning not only LCs but also various chemical systems.

Figure 3. (a) A micrograph of a pinhole with a 200 µm diameter. (b) A polarized optical micrograph, and (c) a schematic illustration of the resultant film with radial molecular orientation created in the irradiated region. The scale bar is 100 µm.

【References】

- 1. T. Kato, Science, 295, 2414 (2002).

- 2. G. M. Whitesides, B. Grzybowski, Science, 295, 2418 (2002).

- 3. S. J. Woltman, G. D. Jay, G. P. Crawford, Nat. Mater., 6, 929 (2007).

- 4. T. J. White, D. J. Broer, Nat. Mater., 14, 1087 (2015).

- 5. A. Priimagi, C. J. Barrett, A. Shishido, J. Mater. Chem. C, 2, 7155 (2014).

- 6. K. Fukuhara, S. Nagano, M. Hara, T. Seki, Nat. Commun., 5, 3320 (2014).

- 7. I. C. Khoo, Phys. Rep,, 471, 221 (2009).

- 8. K. Hisano, Y. Kurata, M. Aizawa, M. Ishizu, T. Sasaki, A. Shishido, Appl. Phys. Express, 9, 072601 (2016).